Project Description:

Al-Tuwarqi Group (ATG) plans to develop an integrated steel complex located in the Second Industrial City at Dammam. ATG propose to construct a steelmaking and 1Mt/y billet casting facility. Phase 1 will comprise the following processes:-

- One Twin shell DC electric arc furnace (EAF) – 130 TON

- Two single station Ladle Furnace (LF) – 130 TON

- One Six Strand Billet Caster

ATG has planned to interconnect the proposed steel plant by constructing new 230kV substation in steel plant premises with an LILO interconnection on the transmission line between 230kV Senaeyah BSP and Abqaiq Central substation to avail 250 MVA power from SEC grid for the plant operation. In view of this ATG intends to perform power system studies to validate the plant performance in-compliance with Saudi Arabian Electricity Grid Code.

Studies Performed:

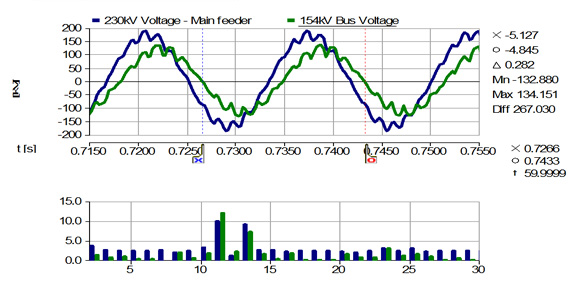

Load flow, short circuit, motor starting studies, Harmonic studies and Voltage flicker studies

Scope of Work:

- Power Quality and Harmonic measurements at SEC interface points (Senaeyah BSP & Abqaiq Central Substations)

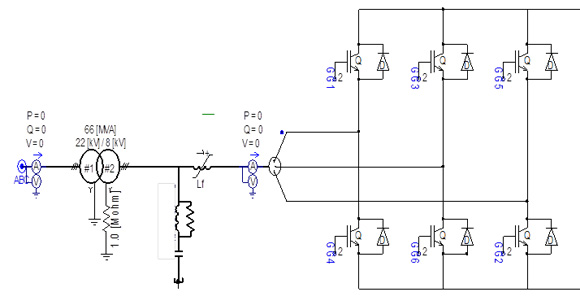

- DC EAF modeling and AC LF modeling using PSCAD software

- Studies to assess the harmonic and voltage flicker levels at PCC.

- Proposals for mitigation measures to suppress the harmonics and voltage flicker problems.

- Validation of STATCOM design and specifications.

- Review of steel plant MV network configuration by performing simulation studies using ETAP software

- Motor starting impact analysis

- Preparation of grid islanding scheme.

Project Highlights

Client: Arab Steel Co (al Tuwarqi Group)

Project Value: SR 650,000

Contract Period: Completed